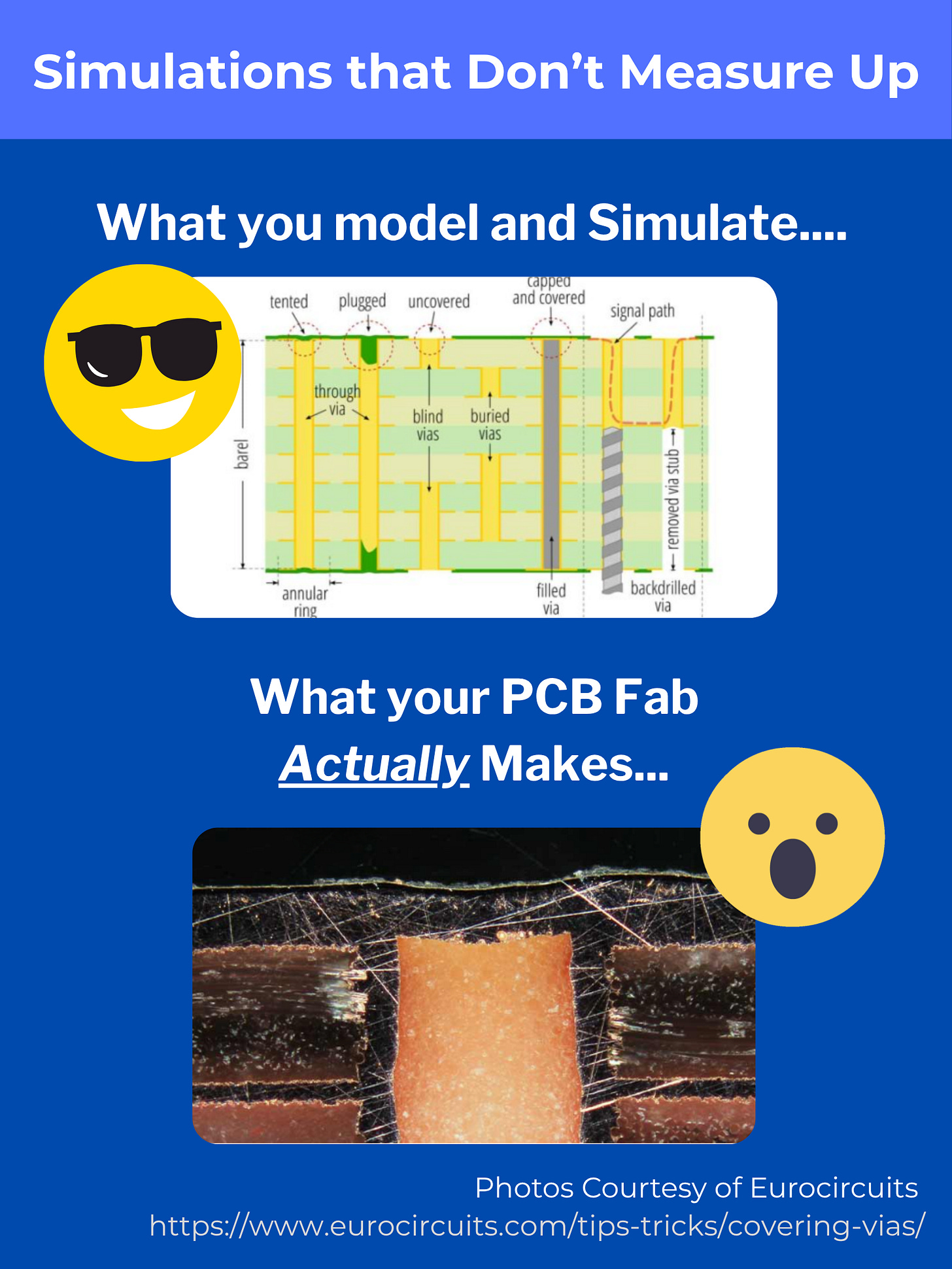

Why Your Simulations Don’t Measure Up

Why Your Signal Integrity Simulations Are Lying to You (And How to Fix Them)

This week I saw a LinkedIn post from my friend and engineering SI/PI expert Bert Simonovich, of Lamsim Enterprises. He was talking about a recent article he published in the Signal Integrity Journal on the effects of anisotropy in PCB materials. It immediately brought back memories of my days at Transline Technology, when I worked closely with RF and microwave engineers. A question I heard over and over again was:

"Why don’t the boards you send me match the careful simulations I made before fabrication?"

It’s a fair question that deserves an answer—but as I’m sure you know, it’s not a simple one to answer!

Bert and I discussed this very topic of his recent article on the EEcosytem podcast earlier this year, as he was preparing his paper for DesignCon. And while I don’t claim to have the deep technical expertise of people like Bert Simonovich, Eric Bogatin, Steve Sandler, Heidi Barnes, or John Coonrod, I’ve had the good fortune to learn from many of them over the years. Between my time hosting the OnTrack Podcast at Altium and now building The EEcosystem, I’ve been a student of some of the industry’s best.

So, I thought this would be a good week to revisit this common question and share what I’ve learned from the experts about why your simulations often don’t measure up—and how you can close the gap between expectation and reality.

1. The Problem with Perfect Models

Most signal integrity tools assume ideal conditions—pristine transmission lines, isotropic materials, flawless layer registration, and perfectly controlled impedance. But the real world doesn’t work that way.

As Bert says, “Simulation is only as good as the assumptions and models behind it.”

2. Anisotropy Is Real (and Often Ignored)

A lot of engineers plug a single dielectric constant (Dk) into their simulation, but materials like FR-4 and even high-performance laminates like Rogers or Megtron have directional properties. That’s called anisotropy, and it means the Dk in the XY plane isn’t the same as in the Z-axis. Your signals are taking different paths—and seeing different effective speeds—than your simulation assumes.

3. Manufacturing Tolerances Add Up

Even when simulations are carefully constructed, fabrication throws in real-world variability:

Etch width variation

Resin content shifts

Copper roughness

Glass weave skew

Press-out thickness inconsistencies

At GHz frequencies and above, these small differences have big effects—and simulations rarely model them accurately unless you build that complexity in. (Hint: add D coupons to your panels and use the measured results to inform your future simulations.

4. Return Path Assumptions Are Often Wrong

Professor Eric Bogatin has said it countless times:

“If you don’t control the return path, you don’t control the signal.”

Simulators often assume an ideal return path—smooth and uninterrupted. But vias, cutouts, layer transitions, and power/ground plane swaps can all introduce impedance discontinuities, reflections, and noise coupling. If you’re not modeling the return path explicitly, your simulation will lie to you.

5. Tool Defaults That Sacrifice Accuracy for Speed

Most EDA tools prioritize convenience. Default solver settings, mesh densities, or auto-imported S-parameters might look fine on the surface, but under the hood, they can skip over important physics. Fast results aren’t helpful if they’re wrong. And nothing replaces good engineering judgment built over time. See Rule #9: Always anticipate what you expect the measurement will be (before you start hitting buttons!)

How to Make Your Simulations Tell the Truth

Here’s what leading experts recommend:

Use Measured S-Parameters When Possible

Leverage measured S-parameters for interconnects whenever they’re available—whether from a VNA or a trusted vendor. Then, validate the data for:

Causality

Passivity

Reciprocity

If those aren’t true, your results won’t be either.

NOTE: I worked with Eric on a Keysight Masterclass called How to Read S-Parameters Like a Book. I’ll let you know when it is published on Keysight Learn.

Ask Your EMS or Fabricator for Real Stackup Data

Don’t rely on datasheet Dk at 1 MHz or assume standard layer thicknesses. Partner with your fabricator to get:

Actual dielectric thicknesses

Frequency-dependent Dk and Df

Copper weights and profiles

Resin content and weave style

You’ll be amazed at how much this improves simulation correlation.

Include Real Loss Mechanisms

Ideal transmission lines just don’t cut it. Add in:

Conductor losses (consider Huray roughness models—better yet, Bert Simoniviches’ improved Cannonball-Huray Model).

Dielectric losses (frequency-dependent)

Via stub effects and connector discontinuities

Lossy modeling might take longer, but it’s worth the fidelity.

Validate with TDR and VNA Measurements

Before you send out additional prototypes, correlate simulation results with:

TDR (Time Domain Reflectometry) for impedance and reflections

VNA (Vector Network Analyzer) for S-parameters

If the real-world measurement disagrees with the simulation, it’s time to revisit your assumptions, not your board layout (yet).

Model Return Paths Explicitly

Include reference plane changes, via stitching, decoupling capacitor positions, and any likely path discontinuities. Assume nothing. Model everything.

📚 Want to Dive Deeper? Start Here:

📖 Books

Signal and Power Integrity—Simplified by Eric Bogatin

High-Speed Digital Design: A Handbook of Black Magic by Howard Johnson & Martin Graham

Signal Integrity in Practice—by Donald Telian

📄 Articles & Papers

“Avoiding Garbage-In-Garbage-Out (GIGO) with Field Solvers” — Bert Simonivich, Signal Integrity Journal

How Interconnects Work: Modeling Conductor Loss and Dispersion — Yuriy Schlepnev, Signal Integrity Journal

Signal Integrity and Layout: Learning to Partner— Donald Telian, Signal Integrity Journal

🌐 Online Resources

The EEcosystem Masterclass: Transmission Lines 101 – Our foundational video series with Dr. Eric Bogatin

💬 Final Thoughts

Simulations are a critical part of modern design—but they’re not infallible. They’re only as good as your assumptions, models, and data inputs. The great news is: you don’t need to be a Ph.D. or a field solver ninja to get better results. With accurate material data, solid measurement practices, and a little mentorship from the legends in our industry, you can make your simulations far more predictive—and a lot less painful.

If you've ever been burned by a simulation mismatch, I'd love to hear about it. What’s the worst “simulation looked great…scope (or VNA) said nope” moment you've had? Share in the comments, or drop me a line. We might feature your insight here in future posts!